Machining, Assembly, & Painting of Cast Iron Components

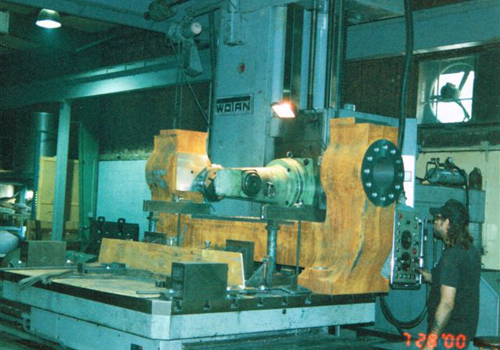

The project highlighted here exemplifies our ability to provide complete manufacturing services, performed to exact specifications, with tight lead times. This mixing mill was designed for use for a rubber and plastic mixing application. Components were delivered to us as a raw casting, the customer needed it to be fully machined, finished, and assembled.

The machining process required the use of our horizontal and vertical boring mills, which are all CNC equipped, as well as our radial arm drill and hydraulic press. Quality was maintained throughout the machining process with dimensional and visual inspections to maintain the required tolerances of +.001”/-.000”. The 10 caps and base frames, and the 20 bearing housings were then painted and shipped to the customer. The entire project was completed in less than 12 weeks. To learn more about this project, or the processes used to manufacture it contact us directly.

Process Highlights

Work with client to assist in choosing a foundry for iron castings and machining allowances for raw castings from outside vendor.

Machining process of machining castings using lathes, horizontal and vertical boring mills and assembling some pieces together.

Finished products after Q C and painting.

Work with client to arrange a cost effective transportation solution.

Specifications of this Custom Manufactured Mixing Mill

| Product Description | Mixing Mill | ||

| Custom Manufacturing Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | Horizontal & Vertical Boring Mills Radial Arm Drill Hydraulic Press |

||

| Tightest Tolerances | +.001”/-.000” | ||

| Material Used | Cast Steel | ||

| Material Finish | Painted | ||

| In process testing/inspection performed | Dimensional Inspection, Visual Inspection | ||

| Industry for Use | Rubber & Plastic Mixing | ||

| Volume | 10 Base Frames, 10 Top Caps, & 20 Bearing Housings | ||

| Delivery/Turnaround Time | 8-12 Weeks | ||

| Standards Met | Customer Specifications | ||

| Product Name | Two Roll Mixing Mill Castings | ||

| Why did you choose this project to show case? | This project shows that GMW is capable of taking a project & completing from start to finish with on time delivery |